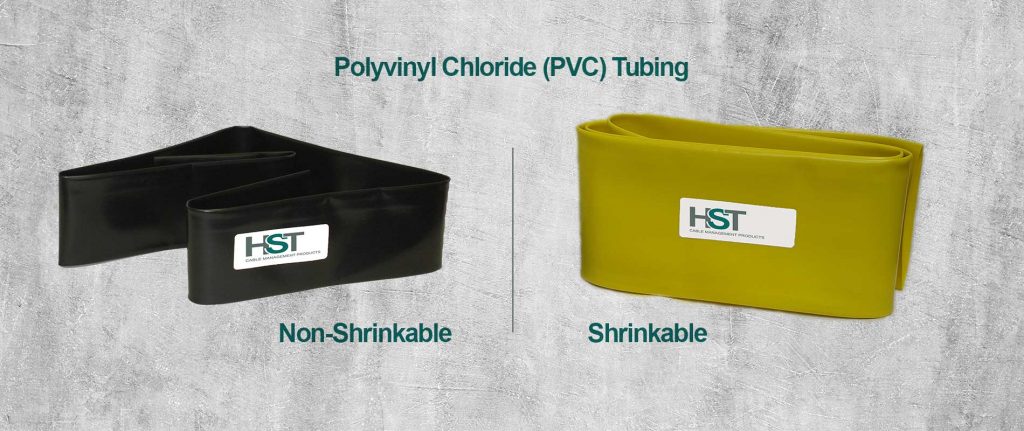

A critical distinction within PVC tubing is between shrinkable and non-shrinkable types. Understanding the differences between these two can help you choose the suitable material for specific applications. Let’s dive into the key differences between shrinkable and non-shrinkable PVC tubing.

Definition and Composition

Shrinkable PVC Tubing:

Also known as heat shrink tubing, shrinkable PVC tubing (Part number: CS-SPVC) is designed to reduce size when exposed to heat. This tubing is typically made from a thermoplastic material that contracts upon heating, forming a tight seal around the objects it covers.

Non-Shrinkable PVC Tubing:

This type of tubing maintains its original size and shape regardless of temperature changes. Non-shrinkable PVC tubing (Part number: CS-NPVC) is used where dimensional stability is crucial and no heat shrink properties are required.

Applications

Shrinkable PVC Tubing:

Electrical Insulation:

It provides excellent insulation for electrical wires and connections, preventing short circuits and protecting against environmental damage.

Cable Management:

Organizes and protects bundles of cables, ensuring a neat and professional appearance.

Mechanical Protection:

Offers protection to delicate components from abrasion and environmental factors.

Sealing and Repair:

Ideal for sealing and repairing damaged insulation or providing a waterproof seal.

Non-Shrinkable PVC Tubing:

Protective Covering:

Serves as a protective covering for wires, cables, and other components without needing heat activation.

Construction and Industrial Applications:

They are used in various construction and industrial applications requiring flexible, durable tubing.

Installation Process

Shrinkable PVC Tubing:

The installation of shrinkable PVC tubing involves placing the tubing over the object to be covered and then applying heat using a heat gun or other heat sources. The tubing shrinks uniformly to fit tightly around the object, forming a secure seal.

Non-Shrinkable PVC Tubing:

Installation is straightforward and does not require any heat application. The tubing is cut to the desired length and fitted over the object. If necessary, it can be secured using clamps, adhesives, or other fastening methods.

Properties and Performance

Shrinkable PVC Tubing:

Heat Sensitivity:

Highly responsive to heat, allowing it to shrink and conform to the shape of the underlying object.

Flexibility:

Maintains flexibility after shrinking, providing a tight yet flexible seal.

Durability:

Resistant to abrasion, chemicals, and environmental factors, making it suitable for harsh conditions.

Non-Shrinkable PVC Tubing:

Dimensional Stability:

Retains its original dimensions even when exposed to varying temperatures.

Strength:

Offers excellent mechanical strength and resistance to wear and tear.

Chemical Resistance:

Resistant to various chemicals, making it suitable for industrial applications.

Cost and Availability

Shrinkable PVC Tubing:

Generally, more expensive than non-shrinkable PVC tubing due to the specialized manufacturing process and materials used. It is widely available in various sizes, colors, and shrink ratios to meet diverse application needs.

Non-Shrinkable PVC Tubing:

More cost-effective and readily available. It has various diameters, wall thicknesses, and lengths to suit different applications.

Shrinkable and non-shrinkable PVC tubing each offer distinct advantages tailored to different applications. Shrinkable PVC tubing is designed for situations requiring a tight, heat-activated seal, such as electrical insulation and cable management. Known as CS-SPVC, it is commonly used in non-irradiated PVC wire and cable applications, wire harnesses, splices, and terminals. It offers quick shrinking, excellent environmental and UV stability, and is a cost-effective alternative to Polyolefin. It provides strong dielectric and mechanical protection, as well as resistance to chlorinated cleaners and grease.

On the other hand, non-shrinkable PVC tubing is ideal for general-purpose use where dimensional stability is crucial, such as protective coverings for wire harnesses, flexible wire protection, chafing protection, and ground-strap protection.

Understanding the distinctions between these types of PVC tubing helps in selecting the appropriate material for specific needs, ensuring optimal performance and durability in various projects. It’s important to note that shrinkable PVC tubing (CS-SPVC) meets UL, CSA, and military specifications, while non-shrinkable PVC passes the UL VW-1 flame test and also meets UL, CSA, and military specifications.

At HST Cable Management Products, we offer both shrinkable PVC and non-shrinkable PVC, with over 30 years of experience, we offer expert advice as well as only the highest quality cable management products.

Interested in learning more about shrinkable and non-shrinkable PVC tubing in El Paso? Call HST Cable Management Products at (800) 880-3212 today!