Hot stamping and thermal transfer methods will be covered in this blog post, comparing their advantages and potential use cases.

The Importance of Custom Identification on Heat Shrink Tubing

Custom identification markers on heat shrink tubing are essential for various industries, including aerospace, automotive, telecommunications, and industrial manufacturing. These markers serve the following key purposes:

Identification:

Markers make it easy to identify wires, cables, and components, helping streamline assembly and maintenance processes.

Traceability:

In highly regulated industries, tracing a wire’s origin is vital for compliance and safety.

Durability:

In harsh environments where chemicals, moisture, and heat can degrade standard labels, heat shrink tubing provides long-lasting identification to withstand these conditions.

With the right identification method, labels can last for years while remaining legible and intact. Let’s explore the two main methods used for adding custom markers to heat shrink tubing.

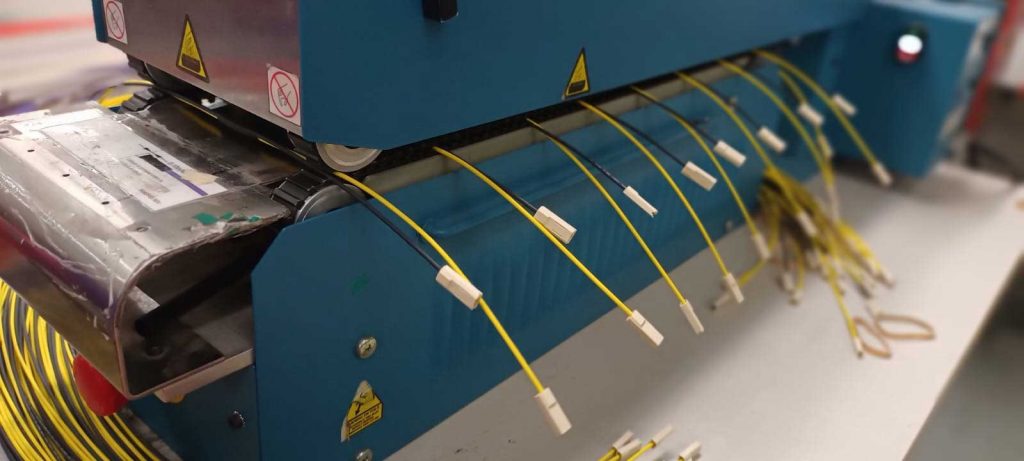

Hot Stamp Heat Shrink Tubing

One of the most traditional methods for printing identification markers on heat shrink tubing is Hot stamping . The process involves using a heated die or mold to press a foil or ink ribbon onto the tubing, transferring the custom text or image.

Advantages of Hot Stamping:

Durable Printing:

Hot stamping offers excellent durability and resistance to environmental factors like moisture, heat, and abrasion. Once imprinted, the identification stays intact, making it ideal for long-term projects.

Simple Setup:

Hot stamping machines are relatively easy to set up and maintain, which makes this method a cost-effective solution for companies that need to print in bulk.

High-Temperature Resistance:

The printed image or text created by hot stamping is resistant to high temperatures, which is crucial in environments where cables may be exposed to extreme heat.

Limitations of Hot Stamping:

Limited Customization:

One drawback of hot stamping is its limitation in terms of graphic detail. Complex logos, barcodes, and intricate designs may not come out as clearly as they would with other printing methods.

Slower Printing Speed:

Compared to thermal transfer printing, hot stamping can be a slower process, especially for more complex projects with varying identifiers.

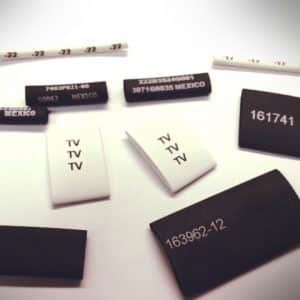

Thermal Transfer Heat Shrink Tubing

Thermal transfer printing is a more modern and flexible option for creating custom identification markers on heat shrink tubing. This method uses heat to transfer a wax, resin, or wax-resin combination from a ribbon onto the tubing, creating the desired marking.

Advantages of Thermal Transfer Printing:

High-Resolution Graphics:

Thermal transfer printing excels in producing highly detailed and sharp graphics. Barcodes, logos, and serial numbers can be printed with great precision, making this method suitable for complex identification needs.

Fast and Efficient:

For companies that need to print a high volume of custom markers with varying text or images, thermal transfer printing is highly efficient. It can quickly produce large quantities without sacrificing quality.

On-Demand Customization:

Thermal transfer printers allow for easy customization. You can print different identifiers for each piece of tubing, enabling on-the-fly updates or last-minute changes to a design.

Wide Range of Materials:

Thermal transfer ribbons come in a variety of materials, each suited to different environmental conditions. This versatility allows companies to choose the best option for their specific needs, whether it’s high-temperature resistance, UV protection, or chemical resistance.

Limitations of Thermal Transfer Printing:

Requires Specific Equipment:

While thermal transfer offers more flexibility in terms of customization, it also requires specialized printers, ribbons, and software. This can be a higher upfront investment compared to hot stamping.

Ink Vulnerability:

Depending on the type of ribbon used, the print may be less durable when exposed to harsh chemicals or abrasive conditions than with hot stamping.

Which Method Should You Choose?

When deciding between hot stamping and thermal transfer printing for custom identification on heat shrink tubing, your choice will depend largely on the specific requirements of your application.

Choose Hot Stamping if you need durability, cost-effectiveness, and long-lasting performance in harsh environments. This method is ideal for basic text or simple identification markers that will be exposed to extreme heat, moisture, or chemicals.

Choose Thermal Transfer Printing if your project requires high-resolution graphics, quick customization, and flexibility. If you need to print complex designs, barcodes, or variable data on each piece of tubing, thermal transfer is the more efficient and precise option.

Hot stamping and thermal transfer printing provide effective methods for applying custom identification markers on heat shrink tubing for wire, cable, and other applications. You can apply hot stamping to shrinkable or non-shrinkable tubing. At HST Cable Management Products, we always customize this process to meet your specific requirements. Hot-stamped heat shrink tubing can feature logos, part numbers, date codes, serial numbers, and more. This permanent process works on heat shrink tubing with 2:1, 3:1, and 4:1 shrink ratios, including regular polyolefin and adhesive heat shrink tubing. Thermal transfer printing, while not permanent, is a cost-effective solution for generating markers as needed. You can apply this process to continuous spools or specific lengths, but it only works on 2:1 polyolefin heat shrink tubing, up to approximately 1 inch in size.

Custom identification on heat shrink tubing is crucial for keeping systems organized, safe, and compliant. By choosing hot stamping or thermal transfer printing, you ensure that cables and components are properly labeled, traceable, and durable enough to withstand tough conditions. If you’re unsure which process to use for custom identification markers on heat shrink tubing, the experts at HST Cable Management Products are ready to assist. Contact us today, and one of our custom printing specialists will guide you in making the best decision.